Riding a two stroke dirt bike is exhilarating! They make a lot of power and have a unique sound. However, do you ever wonder why your dirt bike’s exhaust has a huge bulge in it? Well that bulge is called an expansion chamber or a tuned pipe as it is sometimes referred to, is used to increase power in a two stroke engine.

Two stroke engines are well known for their power to weight ratio, partly because they are simpler and weigh less than a four stroke engine, and also because two strokes create power with each revolution. One of their downsides is inefficiency. This is where the expansion chamber comes in. The expansion chamber works to improve power output and efficiency of the motor.

What Does an Expansion Chamber Do?

The expansion chamber improves your bikes power output by improving the engine’s volumetric efficiency. So how does this tuned exhaust do this? Well, it does this by using pressure waves created in the combustion chamber to basically supercharge your dirt bike.

What’s actually happening in the engine is that during the combustion process, sound waves are created. The expansion chamber uses these sound wave to clean the cylinder of the spent gases from combustion. In the process it draws in a fresh air and gas mixture into its chamber, and then it forces this air and gas mixture into the cylinder. This fills the cylinder to a much higher pressure than could be acheived if the exhaust just vented to the atmosphere, and that is why it sometimes is referred to as “basically supercharging” your engine.

This phenomena was discovered by a German engineer named Limbach in 1938. This technology trickled down to motorcycles when Ernst Degner, a East German motorcycle racer, defected to the west while racing for MZ in the Swedish Grand Prix of 1961.

Two Stroke Engine Ports

Two stroke engines have an inlet port for the fuel and air mixture, and an exhaust port for the gases to escape after combustion. As the piston goes up and down in the cylinder, it will uncover these ports at the proper time.

During normal operation both the inlet and exhaust port could be open at the same time. As a side note this could cause some gas to enter through the inlet and exit through the exhaust without combusting. This is part of the reason why two strokes aren’t considered efficient.

So how does this relate to the expansion chamber? Well an engine produces sound, and these sound waves exit through the exhaust port and into the expansion chamber. As the port is uncovered, exhaust gases rush out of the cylinder and into the expansion chamber creating a pressure wave.

This wave radiating from the exhaust port will have the same frequency as the engine’s speed. For example, can engine operating at 10,000 rpm generates exhaust gases and a pressure wave 167 times per second. This leads to an interesting fact about expansion chambers. The size of the chamber’s length is determined by engine speed and not displacement of the engine.

Early Two Stroke Engine Tuning

When two stroke engine tuning first started, the exhaust was just a cylindrical tube with no changes in diameter. As the exhaust gases rushed out of the combustion chamber, a vacuum was created in the combustion chamber sucking in a new air and fuel mixture.

This simple design created single negative wave. The wave would travel away from the combustion chamber sucking out the exhaust gases and creating a vacuum. Then it would travel back towards the exhaust port. The goal of the engine tuner was to get the exhaust tube length so that the return wave hit the exhaust port at the right time. The speed the engine operates at was most important. Then they would start with a long exhaust pipe and shorten the pipe until they found where it ran best.

This was a difficult process because there is only a small range of engine speed that the sound wave would return to the exhaust port at a correct time. At low rpms the wave would return to soon causing it to bounce off of the port. At too high of speeds, the piston would have already covered the exhaust port.

The two important facts were learned. Pressure waves can be created to pull exhaust gasses out of the cylinder. The speed of these pressure waves is consistent.

How Does an Expansion Chamber Work?

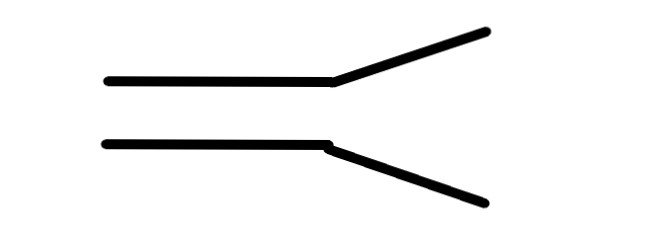

The expansion chamber works by manipulating this “negative” wave so that it can do useful work. Instead of just a straight tube from the exhaust port, the expansion chamber has diverging tubes which gradually increase the tubes diameter.

This is an important feature of the exhaust, because the increasing diameter of the tubes creates a longer returning sound wave and increases suction in pulling exhaust gases out of the cylinder. This suction also pulls in the next air/fuel mixture for combustion. The longer wave is important because it is more likely to find the exhaust port open on its return. The downside of this diverging tube is that it weakens the return wave.

The shape of the divergent cone is important for engine tuning. The length at angle of the tube determines the intensity and length of the returning wave. A short pipe combined with a sharp diverging angle creates a strong pulse similar to that of a straight pipe exhaust. While a long and gradual divergent cone will have a small weaker pulse, but the wave will have a longer duration.

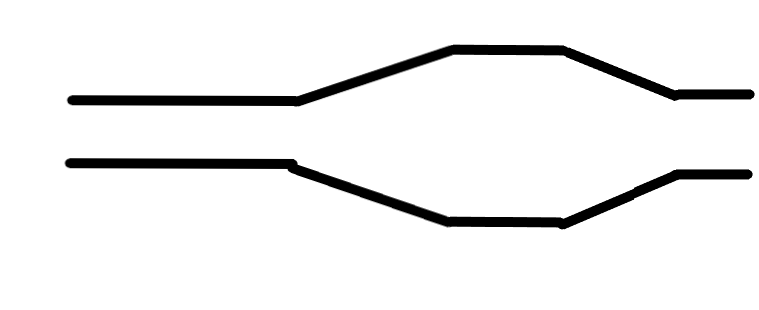

The downside of only using a diverging pipe is that sometimes the vacuum created by the expanding gases can suck some of the fresh air/fuel mixture out of the combustion chamber. To solve this issue, a converging pipe is placed at the end of the of expansion chamber.

The converging cone reflects positive waves back towards the exhaust port. If the converging pipe is properly designed, it will stuff the fresh air/fuel mixture that was pulled into the exhaust back in the combustion chamber. It will force the mixture in through the exhaust port right has the piston closes the port. This increases the mass of the air and fuel mixture in the chamber which basically supercharges the engine and increases power. It is a type of inertial supercharging. This process can be broken down into three key parts.

Expansion Cycle

There are three key parts to the expansion cycle: Blowdown, Transfer, and Port Blocking.

Blowdown: As the piston descends, it exposes the exhaust port. The exhaust flows out of the combustion chamber without aid from the expansion chamber. The first portion of the exhaust pipe from the port to the diverging tube is called the header pipe, and it has a uniform diameter. Because the header pipe diameter is constant the wave energy is preserved. There is no expansion needed at this point in the cycle.

Transfer: When the exhaust pressure drops to atmospheric level, the piston uncovers the transfer ports. At this stage, the out-going acoustic wave from combustion hits the increase in diameter of the expansion chamber creating a negative pressure wave. This negative pressure wave returns to the exhaust port. This negative pressure (vacuum wave) sucks in a fresh air/fuel mixture from the engine’s crankcase and pulls it into the cylinder. Another purpose of this vacuum wave is that it keeps exhaust gases out of the crankcase. The downside is that the negative pressure can actually pull the fresh air/fuel mixture into the exhaust port before the engine can combust it. The solution to this problem is port blocking.

Port Blocking: When the piston is on its way back up for the combustion stroke, the exhaust port is still open. This is an avoidable problem with two stroke engines because they don’t have valves. The solution for this issue is the expansion chamber. The pressure wave reflected from the expansion chamber is timed so that it hits the exhaust port right before the piston closes the port. This return wave forces the fresh air/fuel mixture back into the combustion chamber. The return wave is created by the converging section of the expansion chamber. This wave is sometimes referred to as “port blocking” since it doesn’t allow any fuel out of the open exhaust port.

Signs of a Bad Expansion Chamber

The expansion chamber relies on diverging and converging diameters to create an acoustic wave. Keeping your chamber undamaged is crucial to its operation. Unfortunately this is easier said then done since there are tons of opportunities for damage on a dirt bike.

Dents in the expansion chamber will impact your bike’s performance. These dents can affect the direction of the acoustic waves and even the timing. That is why it is crucial to keep your chamber safe. While your bike can function with a dented chamber, its best to pull out the dents or replace the chamber if its unrepairable.

Conclusion

The expansion chamber plays a critical role in your bikes performance and efficiency. Its size and shape is matched specifically for your engine. While you may not have realized it, the chamber actually “supercharges” your engine. Be sure to protect your exhaust and add a protective plate if you plan on doing serious off-roading.